- 15 sizes (Mini, #1, #2, #3, #4, #5, #6, #7, #8, #8-C, 9, #9X, Maxi-C, Maxi-O, Maxi XL)

- Fits: Closed Top to 39-1/2” (0 to 1meter) Pipes

- Base Range: 2-1/4” (57mm) to44” (1.1meter)

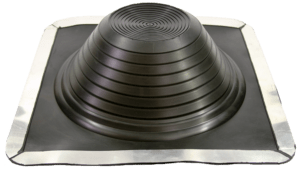

- Weather Protection Made of EPDM orHigh Temp Red or Gray Silicone, these flashings are compounded specifically for maximum resistance to weathering due to ozone and ultraviolet light.

- Available EPDM Colors: Brown, Black, Gray, White, Dark Green, Light Green, Dark Blue, Light Blue, Bright Red, and Terra Cotta

- Cut lines clearly marked to allow for easy installation for multiple pipe sizes.

- A flexible aluminum base allows the flashing to conform to any panel configuration and most roof pitches regardless of pipe location.

- Master Flash®was used to create a new engineering standard for profiled roofing by the International Association of Plumbing and Mechanical Officials (for the Uniform Plumbing Code) and remains the only product listed.

- These products are also listed for use with Type B vents. The addition of fire retarding agents milled directly into the rubber compound created a self-extinguishing feature which enables it to be used with type “B” vents. Listed with IAPMO certification No. 3121

Standard Mini-Master Flash® Extra Features:

- Smallest flashing available

- Specifically Designed for Solar & Electrical Applications

- Fits: Closed Top to 1” (0 to 25mm) Pipes • Base: 2-1/4” (57mm)

- Weather Protection Made of EPDM orHigh Temp Red or Gray Silicone, these flashings are compounded specifically for maximum resistance to weathering due to ozone and ultraviolet light.

- Available EPDM Colors: Brown, Black, Gray, White, Dark Green, Light Green, Dark Blue, Light Blue, Bright Red, and Terra Cotta

- A flexible aluminum base allows the flashing to conform to any panel configuration and most roof pitches regardless of pipe location.